- Do you need help? Here Us:

- +86 151 3866 6240

- richard@zzgofine.com

- Mon - Fri: 8am - 20pm

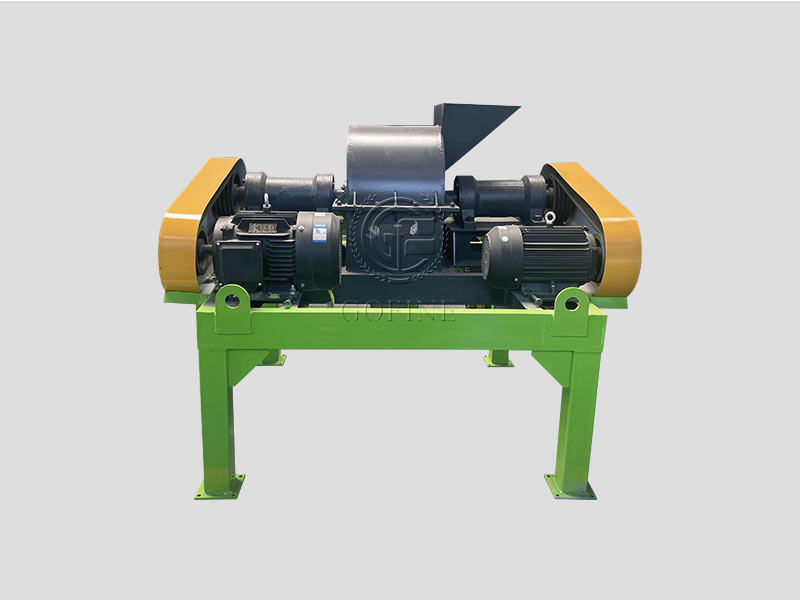

cage crusher

- Home

- Products

cage crusher

Suitable for crushing hard mineral elements with a moisture content of 10%-20%, such as kaolin, clay, bentonite, and widely used in crushing organic minerals, compound fertilizers, urea and other materials.

Products support customization, please contact us if necessary

Sales Hotline:

+8615138666240

+8615138666240

GOFINE Cage Crusher is a medium-sized horizontal cage crusher. It can crush various single fertilizers, especially suitable for materials with high hardness such as monoammonium, diammonium, urea, etc. The machine is designed according to the principle of impact crushing. The inner and outer groups of cage bars rotate at high speed in opposite directions, and the materials are crushed from the inside to the outside through the impact of the cage bars.

The organic fertilizer crusher adopts a two-stage rotor for upper and lower crushing. The material is crushed into fine particles by the upper rotor crusher. Then it is transported to the lower rotor to continue to be crushed into fine powder to achieve the best effect of material powder and hammer powder, and then the material is directly discharged at the outlet.

The organic fertilizer crusher is not designed with a screen bottom, and more than a hundred kinds of materials can be crushed without clogging. Even materials just fished out of the water can be crushed, and will not be blocked due to wet material crushing, causing the motor to burn out and affecting production.

The organic fertilizer crusher adopts a high-alloy wear-resistant hammer head, and the hammer piece is made of forging, which is particularly strong and wear-resistant. It is stronger and more wear-resistant than ordinary hammer heads, which increases the service life of the hammer piece.

The organic fertilizer pulverizer adopts two-way gap adjustment technology. If the hammer is worn, it does not need to be repaired. The position of the hammer can be moved and it can continue to be used. The material particle size can be controlled by adjusting the gap between the hammer head and the liner.

The organic fertilizer pulverizer adopts high-tech technology and can be easily operated by one person, which not only saves manpower but also facilitates maintenance.

The organic fertilizer pulverizer has a centralized lubrication system for oil injection. Under normal operation, the lubricating oil can be injected without stopping the machine.

Not easy to block: The cage pulverizer has strong adaptability to materials with high moisture content, is not easy to block, and has smooth material discharge.

Low operating cost: The cage pulverizer has a simple and reasonable structure and low operating cost. It uses the principle of stone hitting stone and has low wear. It is easy to operate and practical.

High crushing rate: The cage pulverizer has a high crushing rate, fine crushing and coarse grinding functions, is less affected by the moisture content of the material, and has a moisture content of about 60%, which is suitable for crushing medium-hard and extra-hard materials.

Precision production: The cage crusher is carefully selected and finely processed. The inner wall of the casing is lined with polypropylene board, which alleviates the problem of sticking to the wall and difficult cleaning.

| Model | Feed port size (mm) | Power (kW) | Production capacity (t/h) | Overall dimensions (mm) |

| GFLSJ-600 | 380*320 | 11*2 | 4-6 | 1500*1500*1500 |

| GFLSJ-800 | 380*250 | 15*2 | 6-10 | 1500*1400*1500 |