- Do you need help? Here Us:

- +86 151 3866 6240

- richard@zzgofine.com

- Mon - Fri: 8am - 20pm

Fertilizer disc mixer

- Home

- Products

Fertilizer disc mixer

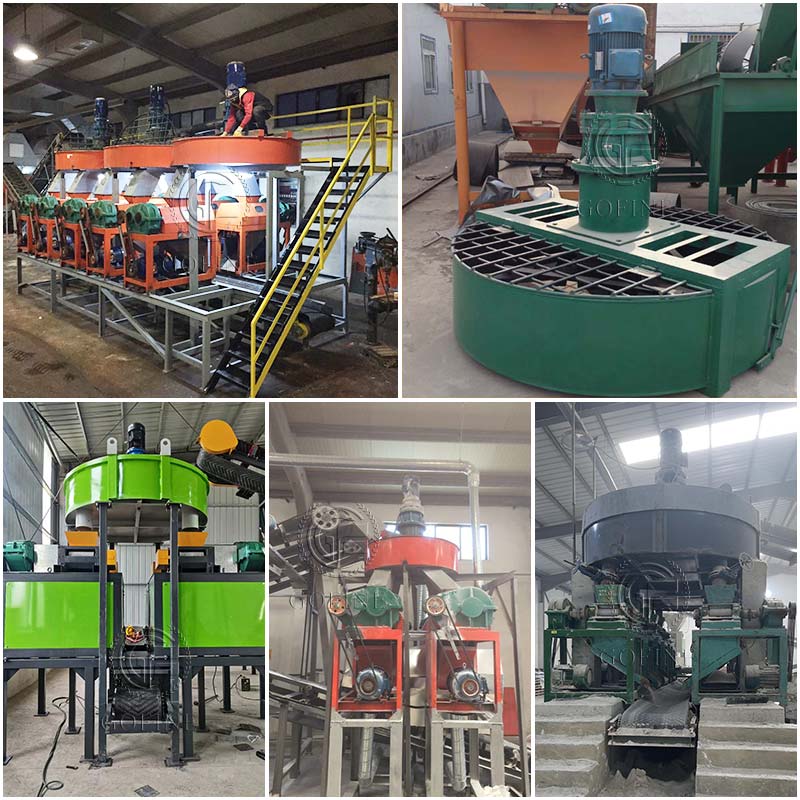

The organic fertilizer disc mixer is a special mixer for the fertilizer industry. It is a mixing equipment produced by our company specifically for organic fertilizer mixers. ...

Products support customization, please contact us if necessary

Sales Hotline:

+8615138666240

+8615138666240

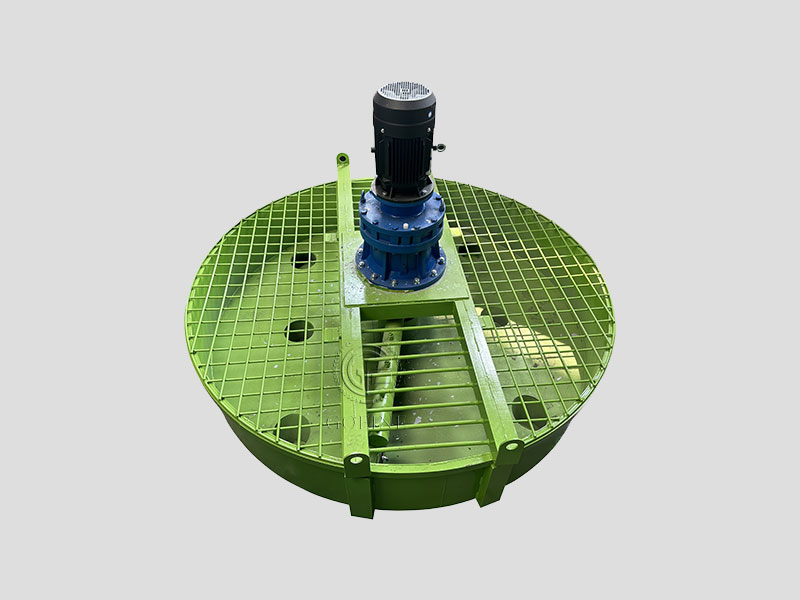

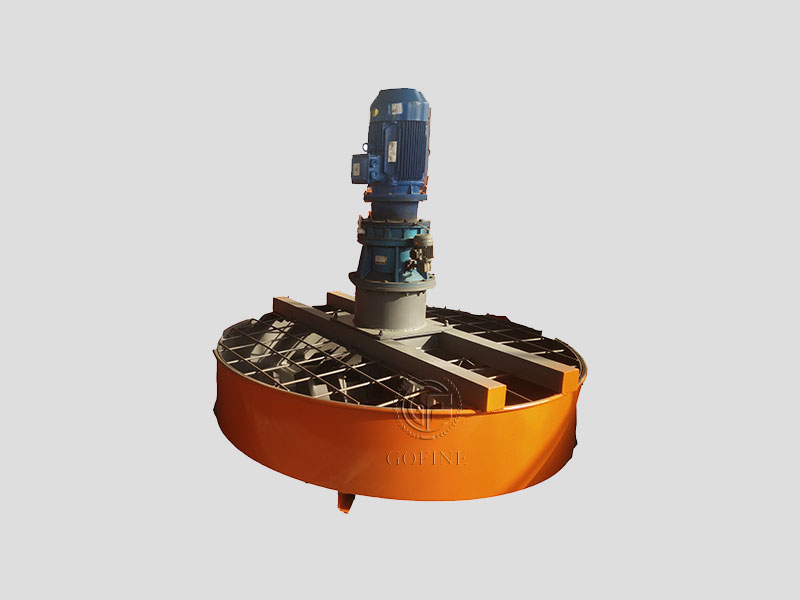

Gofine Organic fertilizer disc mixer is a special mixer for fertilizer industry. It is a mixing equipment specially used for organic fertilizer mixer produced by our company. The equipment consists of a mixing disc, a discharge port, a mixing arm, a bracket, a gear box and a transmission mechanism. The design concept is advanced, the machine is compact and practical. It has the advantages of long service life, fast mixing speed, high mixing uniformity and thorough unloading.

When the disc mixer is working, the motor drives the agitator shaft to rotate through the reducer, and the agitator blades or agitator teeth on the agitator shaft rotate accordingly. The agitator blades exert force on the material in the disc during the rotation process, causing the material to produce circular motion and flip up and down. For fluid materials, the rotation of the blades will generate shear force to evenly mix the different components in the material; for solid materials, the agitator teeth can break up the material clumps and make the solid particles evenly distributed throughout the disc.

1. Continuous mixing: The spiral blades are made of highly wear-resistant special alloys and can be used for continuous mixing operations.

2. Even mixing: The cycloidal pinwheel reducer design is used to ensure the material mixing effect and the equipment operates with low noise.

3. Reasonable structure: The disc mixer is designed with top feeding and bottom discharge, which is simple to operate and convenient for unloading and conveying.

4. Long service life: The disc is lined with polypropylene plates or stainless steel, which has the advantages of not easy to stick to materials, wear resistance and corrosion resistance.

| Model | Mixing output (t/h) | Disc side height (mm) | Disc diameter (mm) | Motor power (kW) | Reducer model | Mixing speed (r/min) | Main plate thickness (mm) | Bottom plate thickness (mm) | Overall dimensions (mm) |

| GFPJ-1600 | 2-4 | 400 | 1600 | 7.5 | BLD15-87 | 16 | 5 | 8 | 1600*1600*1800 |

| GFPJ-1800 | 3-5 | 400 | 1800 | 7.5 | BLD15-87 | 16 | 5 | 8 | 1800*1800*1800 |

| GFPJ-2000 | 4-6 | 400 | 2000 | 7.5 | BLD15-87 | 16 | 5 | 8 | 2000*2000*1800 |

| GFPJ-2200 | 6-8 | 400 | 2200 | 7.5 | BLD15-87 | 16 | 5 | 8 | 2200*2200*1850 |

| GFPJ-3000 | 8-12 | 400 | 3000 | 15 | XLD9-87 | 16 | 5 | 8 | 3000*3000*2000 |