- Do you need help? Here Us:

- +86 151 3866 6240

- richard@zzgofine.com

- Mon - Fri: 8am - 20pm

Customized Liquid Fertilizer Production Line Equipment

Release time:August 28, 2025

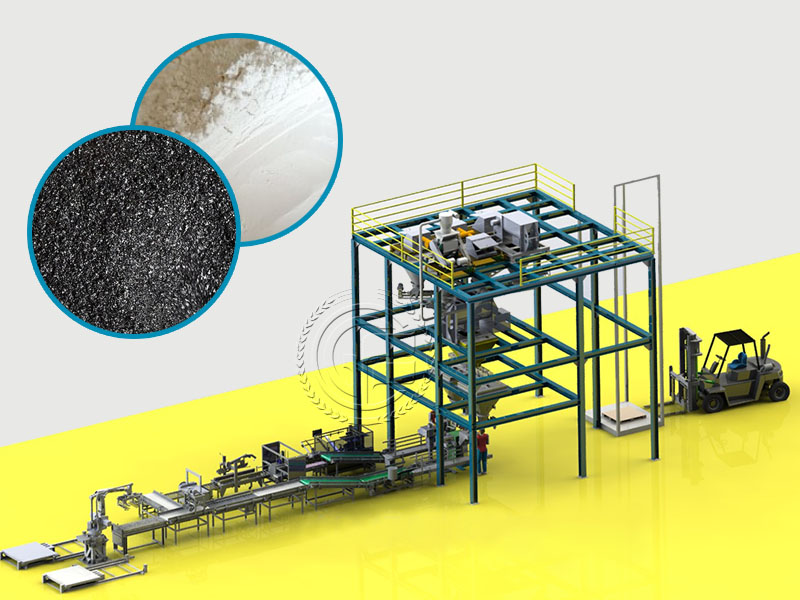

With the global adoption of integrated water and fertilizer farming, demand for liquid fertilizer has surged due to its rapid absorption and high utilization rate. Our liquid fertilizer production line equipment, with its comprehensive intelligent solutions, has become a key enabler for global fertilizer companies in their efforts to expand into the liquid fertilizer market.

The production line focuses on the four key steps of liquid fertilizer production: raw material dissolution, precise compounding, homogenization and filtration, and automated filling. It is suitable for a variety of liquid fertilizer types, including humic acid, amino acids, macronutrients, and trace elements. The core raw material dissolution tank features a double-layer heating structure and a high-speed agitator, enabling complete dissolution of high-concentration raw materials within 30 minutes to prevent clumping. The compounding system, equipped with high-precision metering pumps, precisely injects nitrogen, phosphorus, potassium, and trace elements according to the formulated ratio, with an error control within ±0.5%, ensuring nutrient balance. The homogenization and filtration process uses a three-stage filtration system to remove impurities and undissolved particles, ensuring the clarity of the liquid fertilizer. The filling system supports a variety of container sizes, including 200L drums and 20L jugs, with a filling rate of 300-500 barrels per hour. It also features a weighing and rechecking function to prevent missed or incorrect fillings.

The production line offers flexible customization for different customer scenarios: Small and medium-sized enterprises can choose a compact production line with an hourly output of 1-5 tons, occupying only 30 square meters to meet regional production needs. Large factories can configure a fully automated production line with an hourly output of 10-20 tons, integrating automatic raw material loading, online testing, and data traceability systems, enabling unmanned operation. Furthermore, the equipment’s material-contacting components are made of 316L stainless steel, resistant to strong acid and alkali corrosion. It’s compatible with corrosive raw materials such as humic acid and amino acids, extending the equipment’s lifespan by over 50%.

Currently, this production line has been exported to over 30 countries, including Spain, Brazil, and India. A Spanish customer uses it to produce high-concentration, macronutrient liquid fertilizer for their greenhouse integrated water and fertilizer systems, increasing crop absorption by 25%. A Brazilian customer uses the line to process molasses fermentation liquid, producing an organic liquid fertilizer that is highly sought after by tropical crop growers. Going forward, we will continue to upgrade the equipment’s intelligent control system, adding remote formula adjustment capabilities, enabling global customers to produce high-quality liquid fertilizer at lower costs and higher efficiency, promoting the green and efficient development of agriculture.

Online Message